The Concept

Advanced ultrasonic, electromagnetic and optical techniques, sensors will be developed and combined to perform the volumetric examination of thin gauge weld. The X-Scan device will provide a quick and efficient means of detecting significant defects, including lack of fusion, cracks, etc., in the welded joints. The X-Scan project will bring the following benefits to the inspection of ships:

- Elimination of dangerous radiography

- Elimination for the requirement to work at height

- Reduced set up time and cost

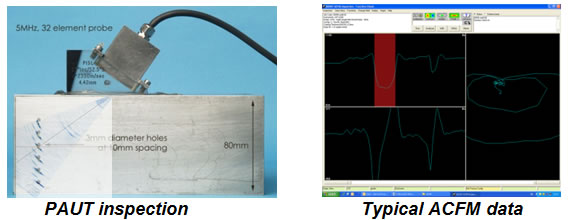

The solution is to combine electromagnetic and advanced ultrasonic techniques to fully inspect thin welded plates and to integrate those with existing technologies (already proven for other applications), giving one complete inspection unit capable of guiding itself without any need to manually identify the weld. The following technologies will be developed and used:

The primary aim of the project is to increase the state-of-the-art of ultrasonic testing and surface inspection techniques so that they can be used on thinner gauges of steel, for the following reasons:

- The use of hazardous expensive and disruptive radiography can be avoided

- The EC's stringent safety regulations can be met

- The quality of ship weld inspection can be maintained, so as to prevent ship's sinking and lives lost

- The competitiveness of the SMEs can be maintained so business is not lost to SE Asia and China.

The project will enable significant technological progress to be made in a challenging area that has seen little development work to date. The new ultrasonic system will provide defect imaging and analysis at much greater convenience and speed than currently exists.